Last Updated on 25.04.2025 by hrushetskyy

Introduction

“Creating things takes a lot of hard work and genius, no doubt. But it takes even more ingenuity and hard work to use the creations wisely, to not let them turn into waste once used, to make sure that the very mother earth we took so much from is not left for the worse because of her own generosity and kindness. It takes a sensitive mind to be aware of one’s ways.”

- D. Thoreau (Walden, 1854)

This quote from a man who has had immense influence on generations of thinkers, philosophers, educators, scientists, politicians, businessmen and common people sums up the majority of problems that the mankind faces today. The evolution of technology has indeed made our lives simpler, easier and more convenient. But in the process, we have invariably impacted the nature – our only source of useful things – in many negative ways.

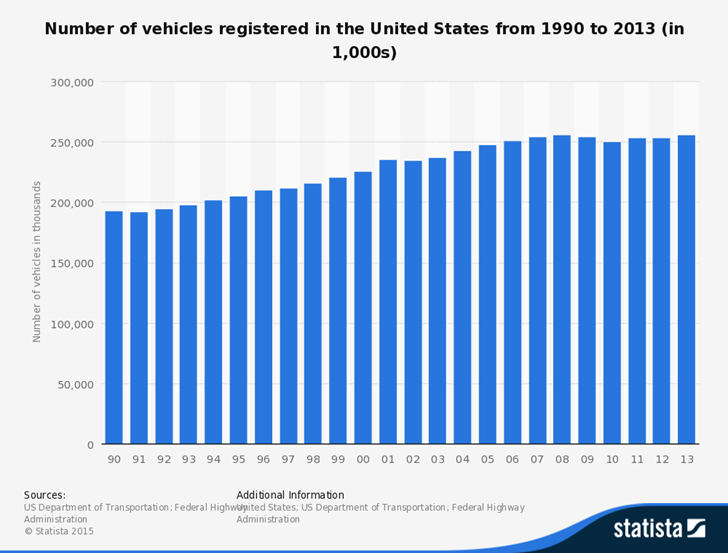

Talking about technology, a mention of vehicles just cannot be avoided. Fuel powered engines were the first exponents of industrial revolution, and the very first thing they were put to use in were vehicles. Today, the number of vehicles all over the world is rapidly increasing. The growth is so steep that nothing but the word ‘exponential’ can even begin to describe it. A statistical insight into the number of vehicles that ‘hit the road’ each year in the United States can be very revealing in this regard.

Referring to numbers published by the Department of Transportation, Federal Government of the United States (collated by Statista), the number of civilian and business vehicles (this excludes armed forces, law and order and other vehicles as government properties) has increased from nearly 180 million in 1990 to over 250 million in 2013, a growth of nearly 40%.

The trend isn’t much different in any other part of the world, either. The very purpose of furnishing these statistics is to show that with increasing number of vehicles, there is an inevitable rise in the quantity of materials discarded upon scrapping of vehicles. Among these discarded materials, tires pose the toughest of challenges. A good quality top-brand car tire can provide up to 20,000 miles of road service. Once that limit is reached, most experts call for a change of tires.

So, what happens to old, used tires?

They are invariably gotten rid of via easy but dangerous methods like burning and dumping. However, tire recycling has evolved to a very sophisticated level. There are many alternatives to these dangerous practices and some of them will be discussed in details in this text.

Applications and Technology Derived from Recycled Used Tires

There are a number of applications of recycled used tires. Some of them can be very straight-forward and don’t need any technical processing while others require some level of processing to elicit utility value, either in the form direct use or in the form of indirect secondary applications, from them.

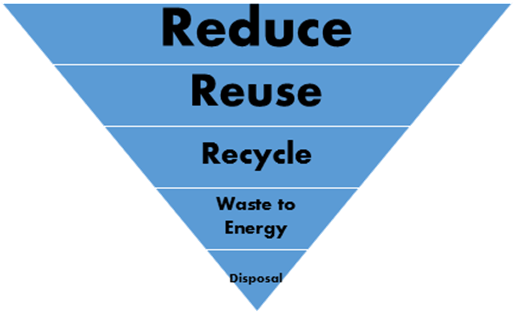

The hierarchy that the Environmental Protection Agency’s waste recycle norms dictate is as follows.

a.Artificial Reefs

Tales from the Bottom – Controversies and Success Stories

Marine reefs are some of the most breath-taking natural habitats. Formed over thousands of years, reefs can host millions of marine species in an environment that’s not only unique but also self-sustainable. Remarkably enough, the most impressive use of recycled used tires that has ever been thought up was to create artificial reefs.

The idea was hailed as revolutionary in the 70’s and the 80’s. Many countries around the world, including Canada, the United States and France decided to dump used car tires into moderately shallow ocean waters to help marine animals and species find a comfortable residence. The idea was to promote tourism and fishing, while getting rid of obnoxious rubber waste.

Even though there were mild success stories of these ‘artificial reefs’, the idea itself seems to have backfired as many natural conservationists have called for retrieval of millions of used car tires from the ocean waters to prevent their long term toxic effects.

The most ambitious of these projects was the Osborne Reef Project in Florida where a huge undertaking by the United States Navy in collaboration with Goodyear (a major tire manufacturer) saw nearly 2 million used car tires being dumped in the Atlantic Ocean.

It was later found out that slow release of heavy hydrocarbon molecules from the tires prevents marine species from making these tires their habitat. About three decades later even bigger projects were undertaken to retrieve these tires from the waters.

Environmental Impact Assessment

Many scientific studies have divulged that, in the long run, rubber tires are not viable options for creating artificial reefs. As a part of the study carried out by a team of marine biologists from the University of Southampton, systemic concentrations of various metals and other materials in species living near or in such artificial reefs were measured. It was found that these species carried unusually high concentrations of mean metals – zinc, lead, copper and cadmium. At many points, these concentrations were thought to be higher than the fatality level for marine species.

Other studies, such as the one endorsed by Russian Journal of Marine Biology in 2002, back these views, claiming that used tires can only speed up the secondary contamination of sea waters.

Related Studies

As the novelty of the concept of using discarded tires for artificial reefs wore off, more and more studies emerged questioning their usefulness in the long run. A private study commissioned and funded by the Nova Southwestern University observed that when tires are used for the creation of artificial reefs, the very motive is to create artificial fish aggregation colonies. As tires lose their relative density underwater, they can be easily moved by strong underwater sea currents. As they keep constantly moving (in a stark contrast to the steady bases of natural reefs), the stability of the whole ecosystem is compromised. Furthermore, the continual emission of metals and hydrocarbons (foreign to marine life) poses biological threats to the species in the long run.

On the other hand, there were some studies, particularly commissioned by the State of Florida and conducted in the first half of the 1990’s that concluded that using scrap tires for the purpose of artificial reefs and fish aggregation was not only economically attractive for the state, but also environmentally useful for the marine species. Such studies, however, were few and far between. Majority of the research available today is in the favour of using natural materials or innocuous materials (like discarded steel frames or specially designed concrete blocks) for artificial reefs.

b. Construction Materials and Civil Engineering

One of the more feasible and economic uses that recycled used tires find is in construction materials and civil engineering. Most of the tires manufactured today are made of high quality mixes of natural and synthetic rubber that is specially designed to withstand high pressure. This particular property comes in handy in their uses in the aforementioned areas of application. Such uses are outlined below.

- Rammed Earth Construction Materials

Rammed earth techniques of durable construction have been around for decades. In these techniques, highly compressed ‘earth’ (sand/soil/clay) is used as the basic building block of a project.

Recycled used tires can be employed to contain this compressed mass of earth in a solid framework, imparting more stability to the structure. Since tire material is relatively less dense, it reduces the further normal load on the base of the building. Simple and cheap materials like cardboard sheets can be used to pack the assembly in what civil engineers call ‘tire bricks’.

- Tire Bales

Tire bales can be described as superior versions of rammed earth tire bricks. They weigh a lot more than a regular tire brick assembly (up to 2,000- 2,200 pounds in some cases) and hence, are only useful in large projects.

A single building using tire bales for outer walls can consume thousands of used tires of regular size.

- Earthquake Proofing

In earthquake prone zones, especially far eastern countries like Japan, recycled used tires are regularly used in the construction materials of houses and other buildings. Tires provide lower overall density to the building, without trading off the stability. Furthermore, as tire are made from rubber – a highly flexible and pliable material – construction bases made using recycled tires have a better flexibility and lesser rigidity. This allows the buildings that use such materials for their bases to stay quake-proof to a certain degree.

Other applications of recycled used tires in construction and civil engineering include:

- River embankments

- Bridge abuts

- Wall fillings

- In asphalt mixes for road construction

- Landfills

- In artificial turf and synthetic surfaces for sports (gymnastics, basketball etc.)

c.Fuel

Even though they take a long time to get ignited, tires are easily flammable once there. They have a high intrinsic calorific value. That’s precisely why, many argue that using tires in construction or landfill purposes is akin to wasting this calorific value. Of course, there are inherent emission issues associated with their direct incineration. Hence, other approaches to harnessing this calorific value and using tires to generate usable fuel have been researched and employed. Today, up to 50% of all recycled mass of tires in the United States is used for the production of tire derived fuel.

- Tire Derived Fuels

This is the commonest form of using tires as fuel. In this, tire remnants are shredded and mixed together to create a solid fuel stock that can be incinerated in a specially designed furnace to generate energy.

Shredded tire parts are devoid of any metal wires or casings. They have a very high calorific value – up to 15,000 to 16,000 BTUs per pound, which is higher than anthracite (12,000 BTU/lb) and bituminous (13,000 BTU/lb).

- Tires as Supplements

Tires can be used in supplementary capacities to aid primary fuels like wood or coal. Tires are often used in what is called a ‘priming’ process – a process that gets the furnace heated, creating enough carbon dioxide to increase the residence temperature so that further combustion of fuel can be facilitated.

- Tires are Used as Fuel In:

- Paper Industry

- Cement Industry

- Mining Industry

- Industrial Boilers

- Thermal Power Plants

- Advantages and Disadvantages of Tires as Fuel

Table 1: Advantages and Disadvantages of Tires as Fuel

| Advantages | Disadvantages |

| Low cost | High zinc residue |

| Better utility | High dioxin and furan emissions |

| Reduces fossil fuel consumption | High percentage of overall carcinogenic emissions |

| Reduces sulphur emissions (SOx) | |

| Reduces nitrogen emissions (NOx) |

d. Recycled Tire Products

In addition to the uses mentioned above, recycled tires have many other applications—often of the more creative variety. These typically don’t require extensive processing, making them easy and cost-effective to repurpose.

- Cattle Accessories

One of the biggest problems that most of the ranchers and farmers across the world face is that of keeping their livestock free of diseases. Most of these diseases originate from the lack of hygiene. Cattle accessories like livestock padding, poultry mattresses and equine mattresses that are made out of recycled tires help prevent the infestation of various bacteria and insects around the livestock.

Such cattle accessories are cheaper than grass or cotton accessories and are much easier to clean. They are also indefinitely durable.

- Moulded Objects

A variety of moulded objects can be made from recycled used tires. These range from heavy ship shock absorbers to tiny rubber casings for electronics and other gadgets.

- Footwear

Another prominent use of recycled tires is in the footwear industry. Many tire companies, designers and high-end boutiques already sell footwear made wholly out of recycled used tires. They have extensive applications themselves – from safety shoes at industrial plants to chic slippers for evening strolls.

- Miscellaneous Uses

There are a number of other miscellaneous uses for used tires. Some involve the use of tires in ‘as they are’ condition (innovative furniture, utility objects, household planters etc.) while other may warrant some processing before usage (backyard kids’ pool, trampoline base, treehouse stairwells etc.).

e.Tire Derived Aggregates

In construction, an ‘aggregate’ is a general term used to describe a custom concrete mixture. The composition of an aggregate is dictated largely by the application it’s supposed to offer. Tire derived aggregates (TDA) have been used in construction, especially where a large quantity of ‘buffer’ material is required (e.g. roadways).

Tire derived aggregates are prepared by mixing a certain ratio of shredded used tires with a ready-mix concrete mixture. The size of the shreds depends upon the application. It typically ranges from 2 inches to 12 inches. Geometrical shapes (regular shapes) of shreds are preferred over irregular shapes.

There are two major types of tire derived aggregates.

- Type A TDA

In type A TDA, the shreds used are, on an average, not wider than 3 inches. They are preferred to be superficially rectangular or circular. Type A TDA are used in residential and commercial building constructions.

- Type B TDA

In type B TDA, the shreds are wider than 3 inches. Type B TDA are often used in large and crude construction projects where fine finish isn’t necessary.

The advantages of using tire derived aggregates over traditional gravel/soil/sand/clay derived aggregates are:

- Very high thermal mass (up to 8 times that of gravel aggregates)

- Low density (lowers the dead weight by up to 66%)

- Flexible and compressible

- Up to tenfold increase in drainage efficiency

- Vibration immunity

f. Rubber Modified Asphalt

Another prominent use of recycled used tires is in improving features of asphalt that’s used for roads and other construction purposes. Rubber modified asphalt, also known as asphalt-rubber, is a mixture of ground tire materials and pre-set asphalt mix. Usually, one or more varieties of asphalt binder chemicals are used to bind both the materials together.

- Manufacturing Rubber Modified Asphalt

Manufacturing of rubber modified asphalt is typically carried out in dedicated plants that act as complements to asphalt mixing facilities. Used tires are first collected and then sorted based on their type/composition. All the metal parts are stripped off these tires before tires are ground to semi-fine (5 to 7 mm) powder. This ground mass of tires is then mixed with asphalt with the help of a binder.

- Rubber-Asphalt-Concrete

Rubber-asphalt-concrete (also known as rubberized asphalt concrete) is an aggregate in which asphalt-rubber replaces gravel content in the concrete mix (either hot or cold mix). Rubber-asphalt-concrete is used in coarse construction projects.

- Advantages of using Rubber Modified Asphalt

- Better binding of asphalt overlays

- Better rutting adjustment in new pavements/footpaths

- Lower maintenance requirements

- Optimum coefficient of friction (good grip for vehicles)

- Improved life of the road/pavement

- Lower skidding and tire noise

g. Steel Manufacturing

Tires and steel are very closely associated. The very solidity that a tire imparts to a vehicle comes from the network of thin steel wires that populate the tire. Before a tire is scrapped and shredded, it first needs to be freed from these steel wires as they are more valuable than the rubber mass of the tire. This is usually done by mechanical defragmenters. There are newer and more sophisticated technologies particularly the one developed by researched at the University of Kyiv that uses highly polar magnetic shock field to separate these steel wires. Such steel mass is the highest in car tires.

What are recycled car tires used for?

Apart from the applications listed above, another important application for recycled tires is in steel manufacturing. Admittedly, use of tires in steel manufacturing is novel, but the prospects are truly encouraging. Globally speaking, over one third of steel manufacturing plants use energy intensive electric arc furnaces that use coal as their primary fuel. Replacing or complementing coal with recycled, shredded tires can be a great way of reducing dependency of such plants on fossil fuel that is more polluting, less calorific and more expensive.

The test runs carried out by researchers at the University of New South Wales, Australia found that using tires in steel manufacturing plants,

- Increases efficient of the electric arc furnace by up to 3%

- Reduces carbon emissions by up to 10%

- Reduces overall energy consumption by up to 3%

h. Gardening

At households, there are umpteen uses for old, used tires. They typically don’t require any processing or preparation. Just some tweaking here and there, and used tires can be put to great utility, especially in gardens.

- Planters

The commonest use of tires in house gardens is as planters. For larger plants, tires can be stacked to create large planters while, for smaller flower plants or shrubs, even one singular tire can suffice. Tires as planters add a whole new dimension to a garden. They are in a stark contrast with the greenery and overall effect achieved is quite pleasing.

- Edge Proofers

In many gardens, there are edges to walkways or parapets. These can frequently cause minor injuries. By arranging tires around these edges, such injuries can be easily avoided.

- Hotbeds

Using a stack of tires to create hotbeds is a great alternative to expensive steel or plastic hotbeds. Tire hotbeds are just as effective and cost nothing in comparison. They are even suited for composting of biomass.

- Mulching

Mulching is required to maintain the soil humidity. Tire shreds can be used in planters as mulches – they don’t decompose, they avoid water wastage and they are easily replaceable.

i. Noise Barriers

Over the past few decades, ill-effects of sound pollution have been extensively documented. One of the major sources of sound pollution in cities and on highways are the speeding vehicles. To reduce the propagation of sound waves from such highways and roads, noise barriers or acoustic barriers are used.

Noise barriers are often constructed in a concave mirror shape so that they not only absorb sound waves, they also attenuate them to such a high degree that they cannot travel much farther.

Traditionally, foam based materials or plain concrete have been used for building noise barriers. However, many studies have shown that recycled used tires can be cost effectively used to build noise barriers that are efficient, effective and easily replaceable.

Advantages and disadvantages of noise barriers constructed using recycled tires are tabulated below.

Table 2: Advantages and Disadvantages of the use of Tires in Noise Barriers

| Advantages | Disadvantages |

| Low cost | Highly flammable |

| Easier availability | High toxicity when burnt |

| Easier replacement | Low stability of its own |

| Better sound absorption | Difficult to build non-permeable barriers |

| Lightweight |

Economic Value

The economic aspect of handling recycled used tires brings forth some interesting ideas.

- Recycling of tires is not profitable unless done on a mass scale.

- Most of the used tires in the United States are either left unattended or disposed of in non-recommended ways. Of the ones that are recycled or reused in some ways, only 50% are put to cost-effective usage.

- Tire derived fuels can save up to 8% as compared to traditional fossil fuels.

- Rubber modified asphalt can save up to $5 per ton when used in quantities of 500 tons or more, in comparison with conventional asphalt mixes.

- There seems to be a large untapped market for grass-root used tire collection and retreading. A single car tire, without its metal meshing, can fetch anywhere between $1 to $2.50 while a large sized truck or tractor tire with metal casings intact can fetch up to $40 in most cities.

Health Issues and Concerns

Even though they are usually deemed highly unlikely, there are a number of health issues and concerns when it comes to reusing used tires in a variety of applications. The most prominent of them are noted below.

- Tires as Artificial Turf

Used tires are shredded and used in the synthesis of artificial turfs that are used at playgrounds and sporting arenas. However, individuals who spend long hours on such artificial turfs are likely to inhale high doses of a variety of heavy volatile organic chemicals that are released continuously by tire materials in the form of micro-particles. These particles are also known to cling on to the shoes or clothes of such individuals, allowing them to be transported into homes and cars.

For children’s playgrounds, tire mulches are used to reduce the impact of a fall. Many children, thus, are constantly exposed to these VOCs that can cause severe respiratory and dermatologic problems in some rare cases.

- Tire Derived Fuels

TDFs pose greater cumulative health risk than tires themselves. They contain higher proportions of VOCs and hence, can cause more health damage to individuals who come in contact with them.

Combustion of TDFs is known to produce furans and dioxins, along with heavy zinc residues that can be lethal if ingested.

- Tires at Home

Tires, when used at home (for gardening or art), do not pose health risks per se, as the exposure is limited. Excessive skin contact, however, can lead to allergies or bruises through which VOCs can enter an individual’s system.

- Others

One of the commonest health hazard posed by used tires lies in the way they are stockpiled at dumpsites. Tire dump sites are often known to harbour insects, rodents, parasites and other pests that can cause health issues to people nearby.

Tire Pyrolysis

What does pyrolysis mean?

Pyrolysis is the process by which a chemical is decomposed, typically in high temperature conditions. Absence of oxygen prevents combustion. If the products of pyrolysis (solids, liquids and gases) are more useful than the pyrolytic chemical itself, pyrolysis can be an effective way of waste disposal.

What does tire pyrolysis mean?

The process by which used tires are thermally decomposed at a high temperature (up to 500 degree Celsius), preferably in vacuum is called tire pyrolysis.

What does tire pyrolysis yield?

Table 3: Used Tires Pyrolysis Products

| Gas Products | Carbon MonoxideCarbon DioxideNumber of small alkanes (from methane to hexane)

Traces of Hydrogen Sulphide |

| Liquid Products | Pyrolysis OilTraces of Aromatic Liquids |

| Solid Products | Pyrolytic Carbon Black (Cs) |

Environmental Concerns and Assessments

A number of reports by private, academic and governmental organizations have more or less held a consensus that used tires that thrown away without proper care pose grave environmental risk.

Fire Hazard

Tires are highly inflammable. Once they catch fire, it’s difficult to douse the flames that the released gases further ignite the fire. Tires are often stockpiled in huge quantities and hence, this fire hazard can become an environmental disaster of huge magnitude.

Highly toxic gases including carbon monoxide and furans are released upon combustion of tires, not to mention the particulate soot that can cause asthma and other respiratory diseases to those who inhale the fumes.

Landfill Problems

For many years, tires have been dumped into landfills. Many studies have found that this practice can be very harmful for the soil quality in the area as tires keep releasing heavy hydrocarbons and high quantities of zinc throughout their life. Groundwater sources are also contaminated due to tires in landfills.

Tire Recycling Systems

Tire recycling process ensures that used tires are stripped of every other material than rubber itself and then either shredded or granulated. There are many variants of recycling systems, but they all follow a similar algorithm of processing.

- Preliminary Shredding

Used tires are stocked and fed to a preliminary shredder that shreds the tires to coarse pieces (up to 8 inches wide).

- Granulator

A granulator grinds tire shred to granules. There are two granulator types, hot (using hot stream of inert gases) and cold (using cryogenic nitrogen).

- Sifter

Sifter sifts steel and other materials from the rubber shreds.

- Fine Grinder

Collected rubber shreds are ground to required sizes using a fine grinder.

- Pneumatic Delivery

Ground particles (‘crumbs’) are then delivered to product management site using pneumatic delivery.

Vulcanization

What does vulcanization mean?

The process by which naturally occurring rubber is more durable and useful by addition of sulphur based accelerators is known as vulcanization of rubber.

Why is vulcanization necessary?

Naturally occurring rubber is not chemically competitive. Despite being highly polymeric, it tends to melt at temperatures above 80 degree Celsius and tends to become very brittle at sub-zero temperatures. These characteristics make natural rubber useless as far as vehicle tires are concerned. By chemically bonding sulphur with rubber, however, natural rubber can be made more durable as sulphur tends to cross polymerize with rubber, imparting it more durability.

Where is it used?

Vulcanized rubber is used pretty much everywhere these days: from vehicle tires to equipment gaskets and from rubber transmission/convection belts to shoe soles.

Vulcanization doesn’t cost much but the value it adds to rubber is tremendous. That’s why, most applications use vulcanized rubber, instead of natural rubber.

Used Tires in Canada

Canada, being one of the advanced countries, has had to deal with its share of tire disposal problems. Compared to other countries, however, these problems seem to be less intensive in Canada, partly due to the fact that it has very sparse population pockets.

The question, although, still needs to be answered.

What happens to used tires in Canada?

Here’s what happens to used tires in Canada.

As many as eight distinct provinces operate Stewardship Programs for used tire recycle. These programs, often funded by public-private-partnership, oversee everything from used tires collection to processing and applications. Following table summarizes these programs.

Table 4: Provincial Stewardship Programs for Tire Recycle in Canada

| Province | Program | Levy |

| Alberta | Tire Recycling Management Association | $4 per unit |

| British Columbia | Financial Incentives for Recycling Scrap Tires | $3 per unit |

| Manitoba | Tire Stewardship Board | $3 per unit |

| New Brunswick | Scrap Tire Board | $3 per unit |

| Nova Scotia | Used Tire Management Program | $3 per unit |

| Prince Edward Island | Tire Recovery Program | $2 per unit |

| Quebec | Quebec Tire Management | $3 per unit |

| Saskatchewan | Saskatchewan Scrap Tire Corporation | $3.50 per unit |

Major applications of recycled used tires in Canada are briefed below.

- Shredded Tires

- Landfills

- Construction

- Drainage facilitation

- Rubber Crumbs

- Tire mulches

- Synthetic turfs

- Fillings

- Buffer materials

- Whole Tires

- Gardening

- Embankment

- Flood barriers

- Wharf bumpers

- Art

- Furniture

- Fuel

- Tire derived fuels

- Pyrolytic chemicals